DA201935337 – ISSUES of CONCERN for COMMUNITY

Representation can be made via the following link or email EPDCustomerServices@act.gov.au

FYSHWICK

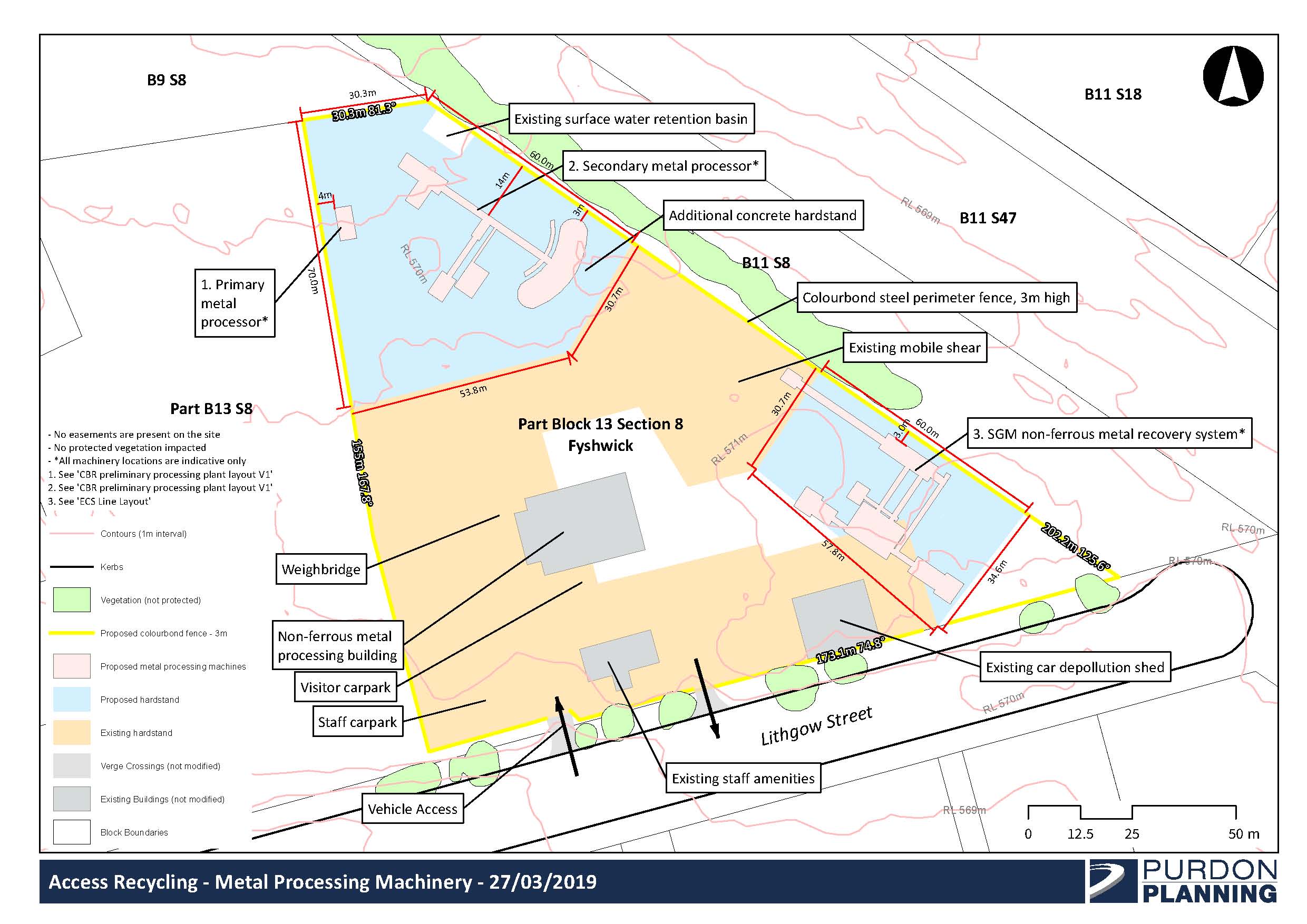

Development Application: 201935337

Address: 15 LITHGOW STREET

Block: 13 Section: 8

Proposal: INDUSTRIAL DEVELOPMENT – RECYCLING FACILITY-Proposed works include concrete slab for the metal recovery system and two portable modular machines used for recycling recovery, 3m high perimeter fencing and associated works.

Period for representations closes: 14/06/2019

Click here to lodge a representation

DA201935337 – ISSUES of CONCERN for COMMUNITY

Proximity to other cleaner retail and commercial businesses

The ACT EPA Separation Distance Guidelines for Air Emissions 2018 must be considered and a distance of 500m applied because the proposal is a new development with major impact for the surrounding mixed use industrial area. Harvey Norman and AllBids and other well established businesses are within 60m of the resulting increased noise and toxic air emissions. The urban infill Eastlake suburb is within 300m of the enhanced operation, the Dairy Road Foreshore development with 10,000 visitors per week is 350m distance and there are residences on Wiluna St within 150m. The Southside Village is 550m on Canberra Ave. No other site has been considered but the similar metal processing of Simsmetal is operated in a large shed at Hume in the general industrial zone. Fyshwick is an area of change with increasing amenity and is becoming a place to visit and enjoy.

Increased machinery noise at the site

The Decision maker is not provided sufficient data to make an informed decision in regard to the impact of noise for workers onsite and in the surrounding mixed use area. There will be significant noise from grinding, shredding and crushing of metal and the use of vibrating separators. The proposed new machinery introduces an Italian Zato metal shredder and hammermill. Based on Zato information the HP1200 high speed hammermill operates at 115-120 dBA equivalent to the sound pressure level of a jet plane on the runway at takeoff or sitting in the front row at a rock concert. This measure applies1m from the sound source.

According to the American Speech-Language-Hearing Association (ASHA), any noise with a decibel level higher than 85 could actually cause permanent hearing damage. Additionally, exposure time is relevant to adverse health effects including hearing loss, sleep disturbances, cardiovascular and psychophysiological problems, performance reduction, annoyance responses, and adverse social behaviour. For every 3 dB sound pressure level (SPL) over 85 dB, the permissible exposure time is cut in half − before damage to hearing can occur. The permissible exposure time for 100dB is 15 minutes and will impact workers at the site. No information is provided in the DA Planning Report in regard to the loudest machine to be installed and no reference is made to health and safety issues.

Absence of a credible Noise Assessment Report

The Noise Report was from a former Access site at Wingfield in Adelaide so there is no recording of noise at the Fyshwick site. The Wingfield operation located in a heavy industry area is 1.35km from the nearest residence and residences on Wiluna St as previously mentioned are within 150m of the site. The applicant makes no effort to advise how such assessment is applicable – or not applicable – to the Fyshwick site. The Decision maker will have no relevant information on the monitoring of ambient noise levels, site topography or the effect of weather influences such as air inversion or how the noise levels of the proposed machinery will cumulatively effect the surrounding premises. The proposed major waste facility and approved heavy rail infrastructure development and truck freight transport all adjacent the open air vehicle processing, also a major waste facility, need to be taken into account by the Decision Maker. Site specific measurement of noise must be addressed in a new scientific noise assessment over time. Importantly the report should include noise contours so that affected parties can see the degree to which they might be impacted.

Proposed noise amelioration

The proposal to erect a 3m high Colourbond fence to reduce noise will hardly be effective when the machinery to be installed goes to a height of 9m and the hammermill and shredder processing cars are operating up to 5m from ground level. The Decision Maker should specify properly assessed noise reduction to align with the DA supporting Document EPA Authorisation (DA supporting document 16) which for metal processing specifies a limit of 65bB on any point at the boundary of the site. With machines operating as close as 4m from the boundary it is necessary for the Decision Maker in the public interest to know the effectiveness of the Colourbond not only for visual screening but also for noise amelioration.

Air Quality

The failure to assess and take seriously the air emissions which are commonly associated with scrap metal processing is apparent in this DA. These can include highly toxic heavy metals and other dusts and particulates which are harmful to human health some of which are known carcinogens. The Decision Maker will be unable to assess how injurious to human health the metal processing proposed in open air will be. The same facility in NSW would be required to operate in a shed such as the Simsmetal major waste facility at Hume.

Scrap metal yards are known polluters and processing facilities will create even more toxic emissions.

Dust and Pollution Controls

This proposal fails to provide adequate controls as required under the EPA Authorisation. Equipment of this size and nature should ideally be fitted with specific pollution control equipment designed to remove all of the identified contaminants likely to pollute the air. No information is supplied as to what was to happen to the remnant waste eg flock from the insides of cars. The Decision Maker cannot assess how the remnant is to be handled, managed, disposed of (eg which landfill?)

Fire Risk

The Decision Maker has no information on the eight fires that have occurred at the Access Recycling site since 2014, the latest on Australia Day eve 2019. The DA only mentions it is not in a bushfire area. Waste facilities and notably metal processing are recognized for fire hazard. Shredders have been known to catch fire. Fires at waste facilities at Mugga Lane, Beard, Pialligo, Belconnen, Mitchell, Fyshwick and Hume have not only caused damage and air pollution but cost emergency services to attend. The air was acrid for workers on Wiluna St on 26 January this year. The mountains of end of life cars at Access Recycling were cleaned of their interiors.

Transport of metal waste

Adam Perry, Director Access Recycling and CRS has previously intended to rail freight metal from a new Fyshwick rail terminal to Port Botany. The operation will bring additional heavy vehicle transport into the single lanes of Fyshwick. Previously trucks came from well outside the 100km regional distance. There is no reduction of such vehicles and all the increased risk of significant traffic accidents and air pollution for Fyshwick is to be considered by the Decision Maker. The application provides no assessment of this impact.

Licence to Operate

Currently Access Recycling operates under a standard environmental authorisation which is not specific to the site but only to a range of processing to include crushing, grinding or separating of materials. The proponent should be required to obtain a waste licence under the Waste Management and Materials Recovery Act 2016. This should be secured before approval can be considered.

Zone objectives

The Decision Maker in consideration of applications in the Merit Track must pay attention to the zone objectives of the Territory Plan. For west Fyshwick there are specific objectives concerning the processing of food and food related activities under Objective l). The applicant has not addressed a most important activity in the area. There are open air eating venues on Wiluna St, at the Dairy Road and at the Fyshwick Fresh Food Markets. Dust containing microscopic particles of heavy metals is not conducive to healthy eating. An expert health assessment on the possible cumulative impact of all the proposed major waste facilities in this Central Canberra urban area would properly inform the Decision Maker.

The activity of recycling facilities using heavy machinery in open air and generating significant noise and dust pollution is not compatible with established food related businesses. The identified Hume Waste Precinct where Simsmetal relocated to from Fyshwick is a more suitable location for motor vehicle processing which certainly should not occur anywhere in the open in an urban situation.

The Issue of Urban Infill

The future suburb of Eastlake planned to grow to 9,000 residents is less than 300m distance from the car processing open air operation. The applicant made no reference to future urban residential and commercial development which is well advanced in planning. Who in Government will take responsibility for such ill-informed decisions that allow heavy and dirty industry especially vehicle processing with its associated toxic particulates into Central Canberra?